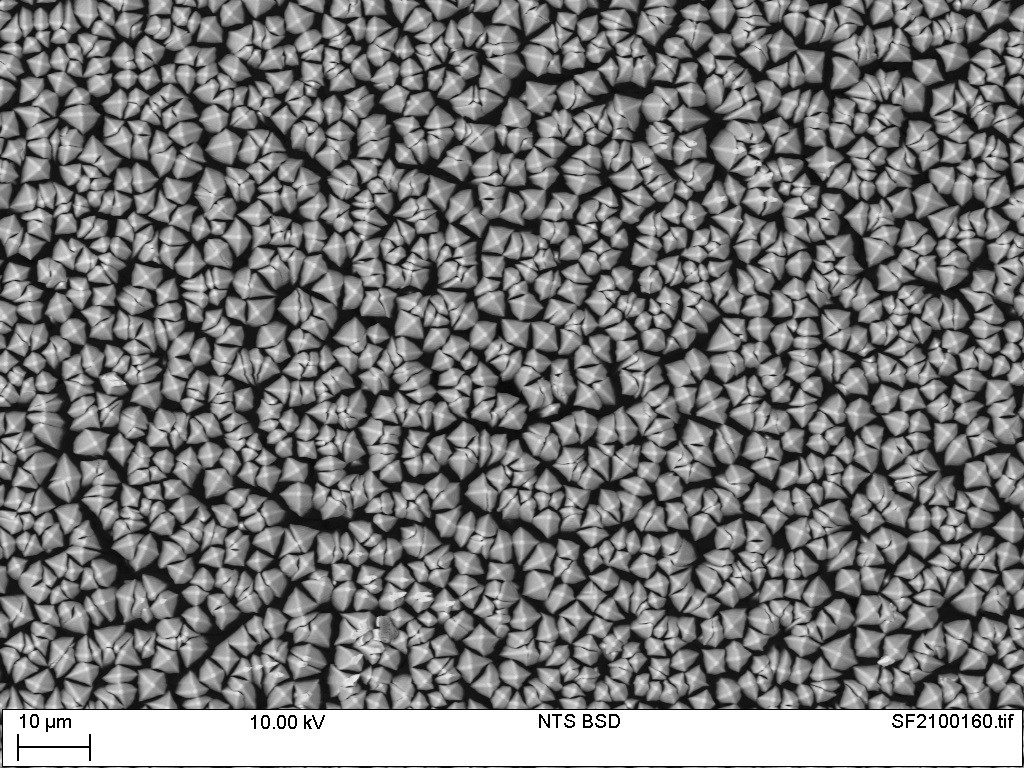

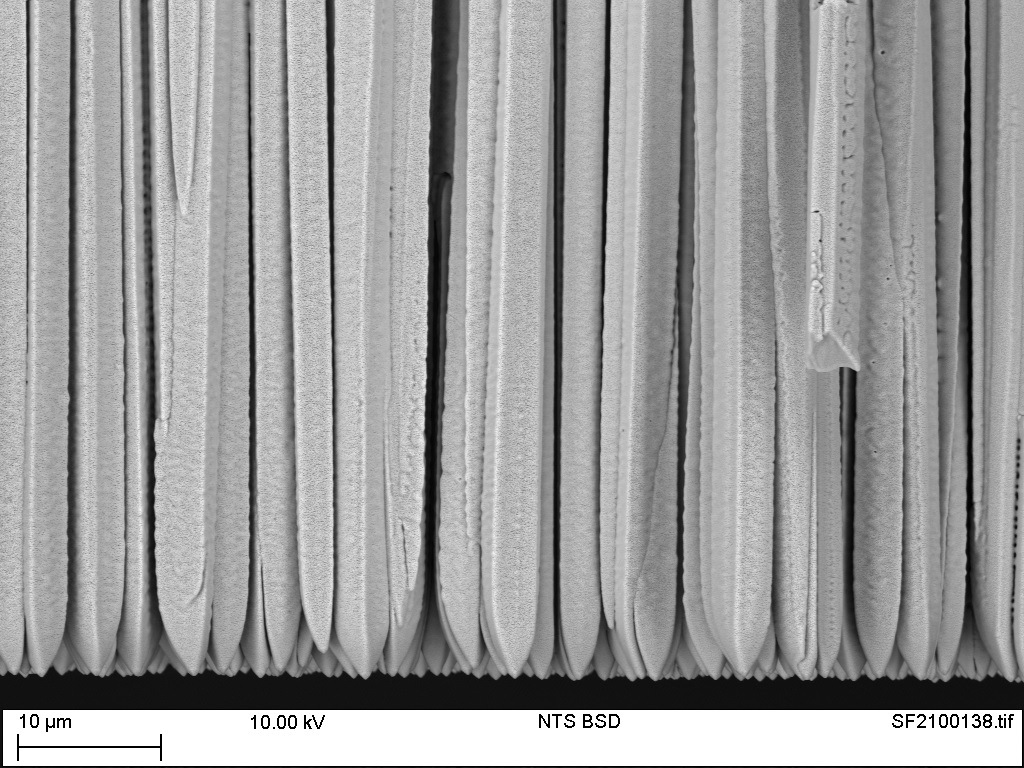

Scintacor’s micro-columnar CsI as seen in a Scanning Electron Microscope (SEM) – separate needles of CsI grow to form a structure that has light-guiding properties in the vertical direction.

Thallium doped micro-columnar Caesium Iodide (CsI) is a uniquely important material in the world of X-ray detection devices. For Scintacor its special properties of high density, high atomic number, efficient scintillation and unusual structure, make it invaluable as the conversion layer for many types of indirect digital X-Ray imaging sensor. At our cleanroom production facility in Cambridge, CsI and Thallium are co-deposited under vacuum by thermal evaporation using in separate ohmically heated boats. In strictly controlled conditions of temperature, pressure, and growth rate, a doped layer forms on fibre optic faceplates (FOPs) or foils- forming first a seed layer then a thick bulk layer of controlled thickness. Under these conditions the primary layer forms millions of vertical ‘needle-like’ crystals of CsI. This mico-columnar structure provides excellent image resolution as each transparent CsI column acts as a separate light pipe, channeling the visible light to the CMOS or CCD sensor below- either through direct contact or via the FOP which is itself a light-guiding medium. It is this lack of sideways scattering in CsI that makes this material such an important ingredient for modern high resolution digital X-Ray scintillators.

Thallium doped micro-columnar Caesium Iodide (CsI) is a uniquely important material in the world of X-ray detection devices. For Scintacor its special properties of high density, high atomic number, efficient scintillation and unusual structure, make it invaluable as the conversion layer for many types of indirect digital X-Ray imaging sensor. At our cleanroom production facility in Cambridge, CsI and Thallium are co-deposited under vacuum by thermal evaporation using in separate ohmically heated boats. In strictly controlled conditions of temperature, pressure, and growth rate, a doped layer forms on fibre optic faceplates (FOPs) or foils- forming first a seed layer then a thick bulk layer of controlled thickness. Under these conditions the primary layer forms millions of vertical ‘needle-like’ crystals of CsI. This mico-columnar structure provides excellent image resolution as each transparent CsI column acts as a separate light pipe, channeling the visible light to the CMOS or CCD sensor below- either through direct contact or via the FOP which is itself a light-guiding medium. It is this lack of sideways scattering in CsI that makes this material such an important ingredient for modern high resolution digital X-Ray scintillators.

Find out more about Scintacors range of CsI scintillators from Scintacor or contact our sales team to discuss your requirements

NEW

Now with the capability of up to 310mm-square active area, we are able to offer the same high-quality scintillators for use in mammography, cone beam CT and fluoroscopy applications.