CsI on Aluminium

High performance Caesium Iodide (CsI) scintillators for X-ray imaging

Scintacor produces an affordable alternative to FOP-based CsI scintillators, with a thin aluminium substrate replacing the Fibre Optic Faceplate.

Like FOP-based scintillators, aluminium substrate-based devices can be custom made in various sizes and CsI thicknesses – from thin layers used in intra-oral dental applications to much thicker layers for high energy and high SNR X-ray applications.

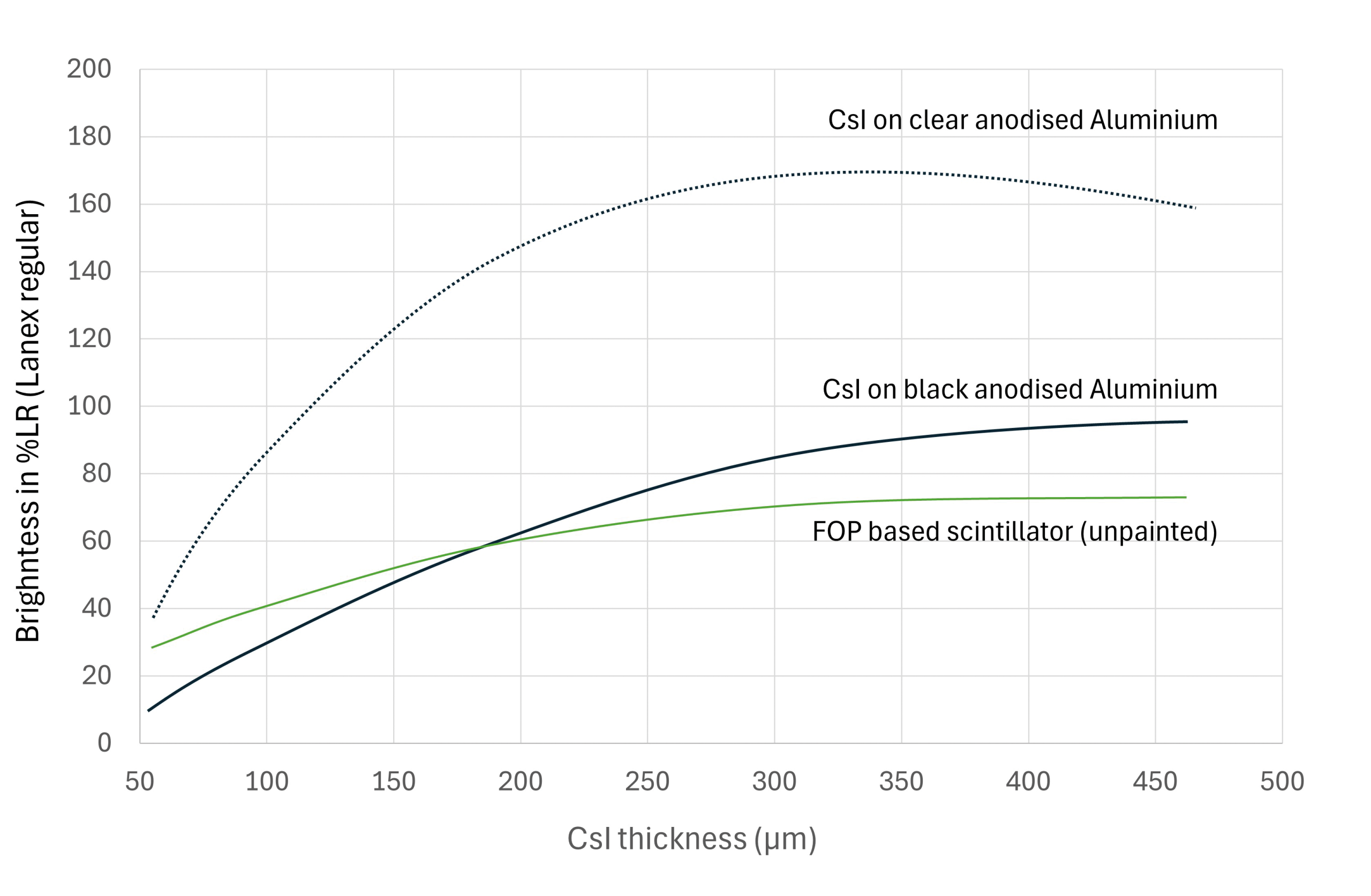

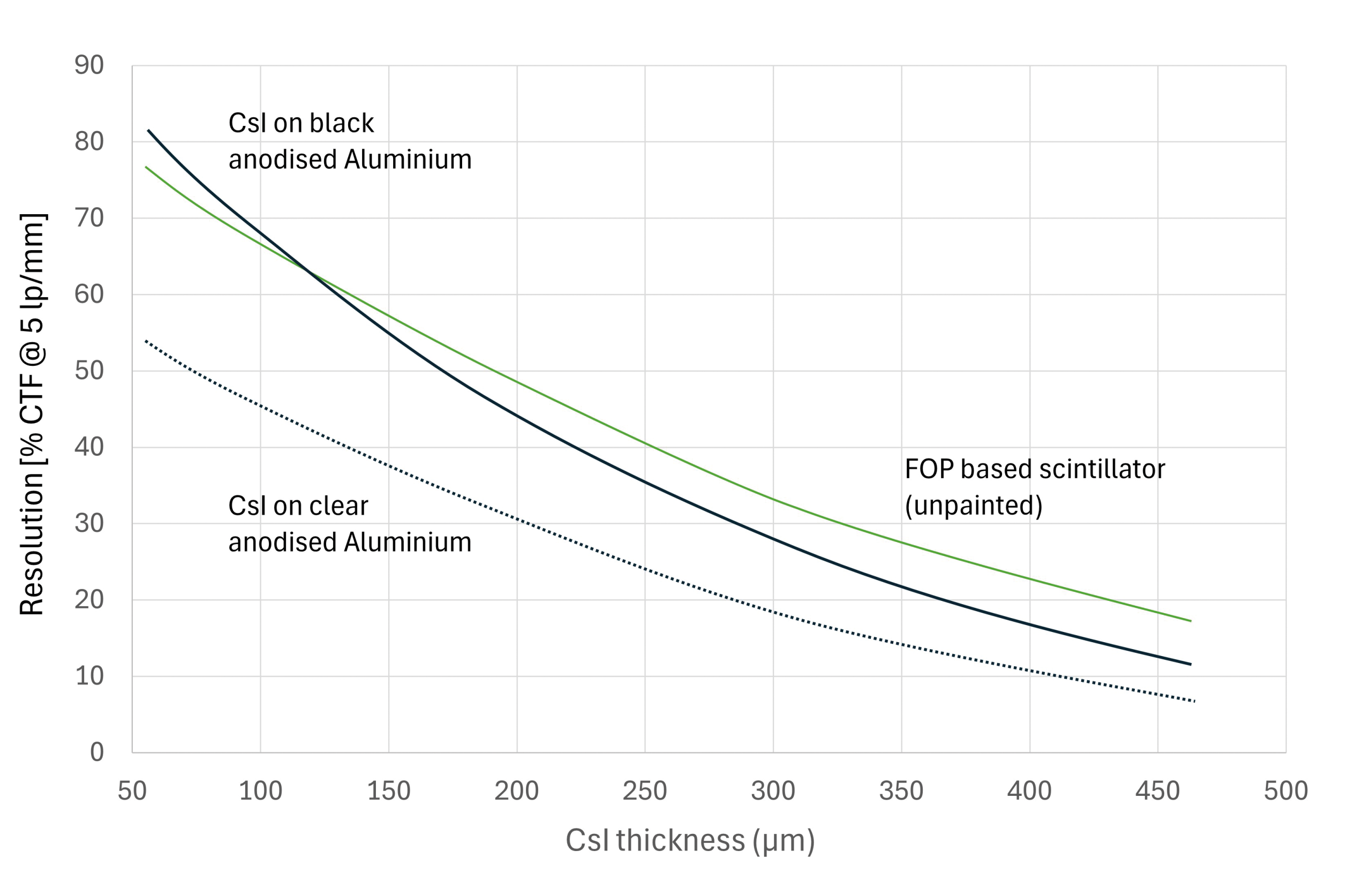

The base substrate can have a black or clear (silver) finish, depending on the application. The black aluminium gives a performance which is closer to that of the FOP-based product, whilst the clear finish is better suited for higher brightness and correspondingly lower resolution applications.

Generally, devices have a small border around the edge for the parylene overcoat to effectively seal in the CsI and prevent moisture ingress.

CsI on aluminium devices still have the light-guiding micro-columnar structure of the Caesium Iodide, and all the benefits of high resolution for a given thickness – that this material is recognised for – but the aluminium is a lower cost substrate, which is especially significant for large area detectors.

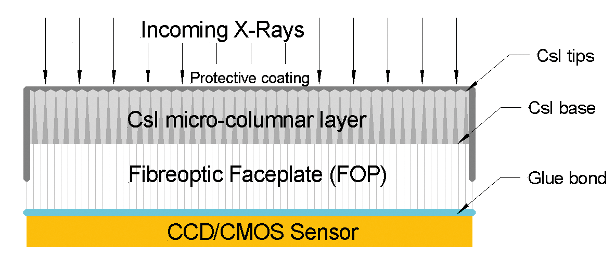

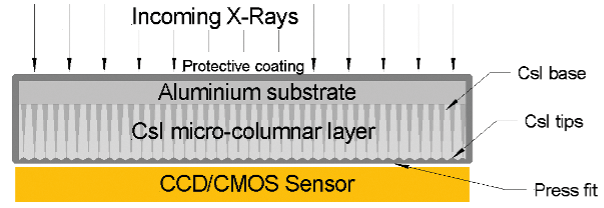

Scintillator architecture

With FOP-based scintillators, the x-rays strike from the tips’ side of the CsI layer and the emitted light is extracted from the opposite ‘base’ side of the layer, passing through the x-ray blocking FOP and into the sensor chip.

With Aluminium devices, the x-rays pass through the aluminium substrate before striking the ‘base’ of the CsI layer. The light exits from the ‘tips’ side of the CsI layer, going directly into the sensor that it is pressed onto.

X-ray performance

With aluminium substrates, it is the CsI layer rather than the FOP which is the primary x-ray blocking layer; as a result, aluminium-based scintillators are more prone to sensor direct hits than traditional FOP-based devices.

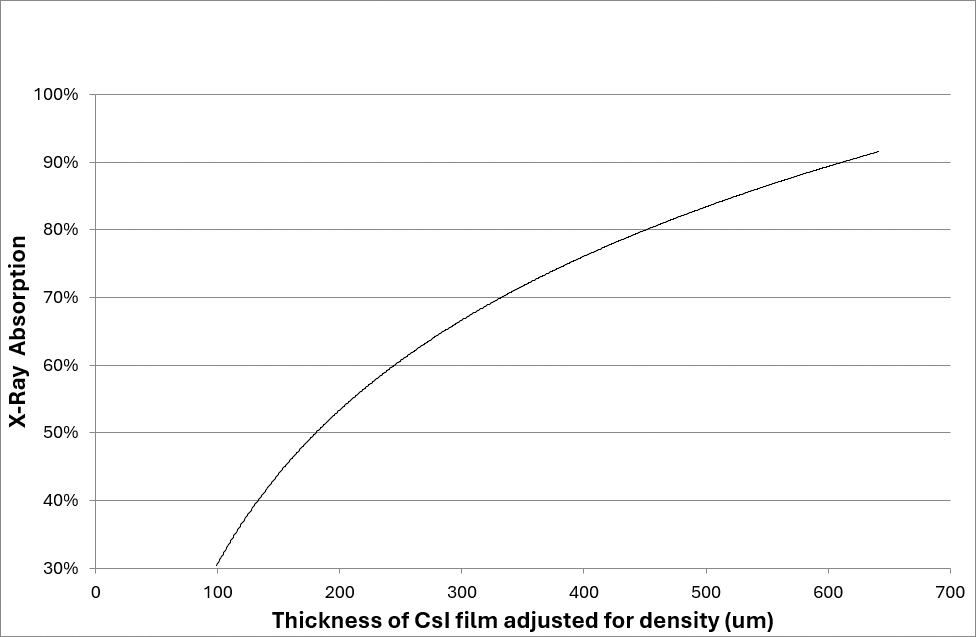

The graphs below show the typical CsI thickness dependence of the brightness and resolution for the aluminium versus a typical FOP-based scintillator, and the x-ray absorption for different thicknesses of that CsI layer:

High Resolution CsI Scintillator

black finish aluminium

(89 x 64 x 0.5mm)

High Brightness CsI Scintillator

clear finish aluminium

(89 x 64 x 0.5mm)

Typical applications

- Intra-oral dental

- Extra-oral such as jaw & head scanning

- Dental CT

- Fluoroscopy

- Mammography

- Scientific x-ray

- Pathology

- Electronics inspection (NDT)

- Security

Why Scintacor?

Scintacor has a wealth of experience manufacturing and developing CsI based products using a variety of substrate materials including glass, aluminium and polymers. We continuously improve and extend our capabilities to meet the needs of your applications, tuning the CsI structure for maximum performance and to offer a large range of customised build parameters. Please contact us to discuss your specific requirements in more detail.

Benefits & Features

- Black aluminium substrate for high resolution,

matching FOP-based scintillator performance - Clear aluminium substrate for higher brightness

and correspondingly lower resolution applications - High resolution micro-columnar CsI scintillator layer

- Choice of CsI thickness to balance brightness, SNR, and resolution

- High sensitivity solid state scintillator to reduce patient x-ray dose

- Edge-sealed fully encapsulated devices to prevent moisture ingress

- Customisable size and shape

- Cost-effective aluminium substrate

Downloads

Technologies

Contact Us

+44 (0)1223 223 060

info@scintacor.com

Contact Form