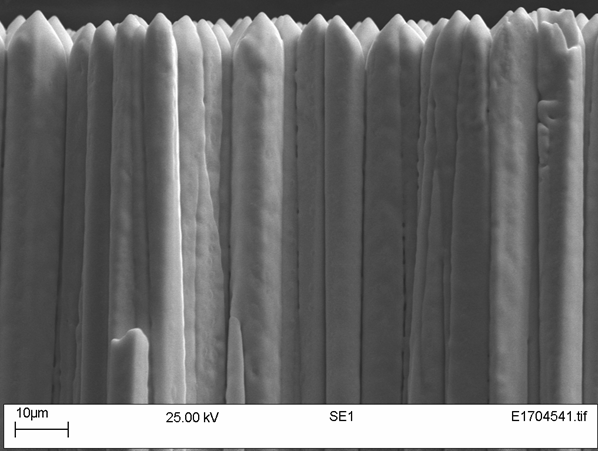

Thallium doped micro-columnar Caesium Iodide (CsI) is a uniquely important material in the world of X-Ray detection devices. For Scintacor its special properties of high density, high atomic number, efficient scintillation and unusual structure, make it invaluable as the conversion layer for many types of indirect digital X-Ray imaging sensor. At our cleanroom production facility in Cambridge, CsI and Thallium are co-deposited under vacuum by thermal evaporation using in separate ohmically heated boats. In strictly controlled conditions of temperature, pressure, and growth rate, a doped layer forms on fibre optic faceplates (FOPs) or foils- forming first a seed layer then a thick bulk layer of controlled thickness. Under these conditions the primary layer forms millions of vertical ‘needle-like’ crystals of CsI. This mico-columnar structure provides excellent image resolution as each transparent CsI column acts as a separate light pipe, channeling the visible light to the CMOS or CCD sensor below- either through direct contact or via the FOP which is itself a light-guiding medium. It is this lack of sideways scattering in CsI that makes this material such an important ingredient for modern high resolution digital X-Ray scintillators.

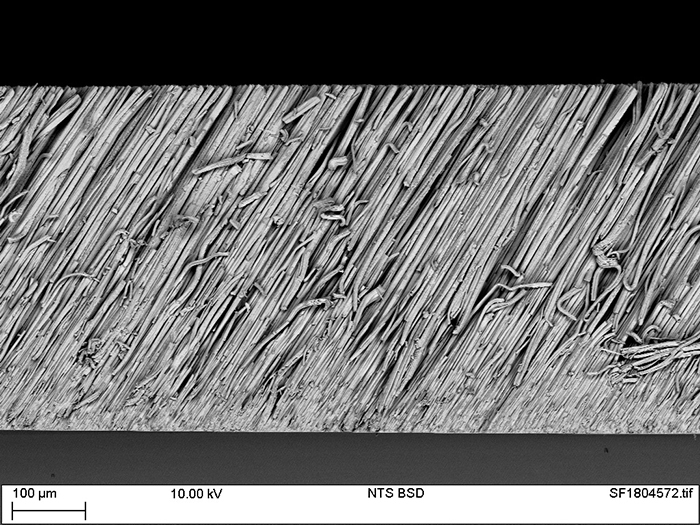

Work at Scintacor continues to explore better and more efficient methods of deposition leading to extended resolution and improved light output performance. An extensive program of engineering work continues to extend our understanding of the subtleties of the material’s behaviour during growth and to appreciate the impact of each of the many process parameters on the material’s performance and environmental resistance. As part of this effort, work has been carried out recently to understand the impact of the direction of deposition on the micro-columnar structure. Samples with CsI deposited at different deposition angles have been cross-sectioned and prepared for imaging using a scanning electron microscope at a local research facility. Through the insight gained in work like this Scintacor continues to improve its production methods, giving benefits to customers in terms of device capability and quality.

For further information contact us by email or visit us at Laser World of Photonics on stand B2123 24th June -27th June 2019 | Messe München Germany.

Author Martin Lewis – Principal Engineer