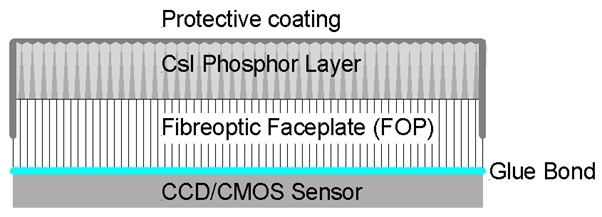

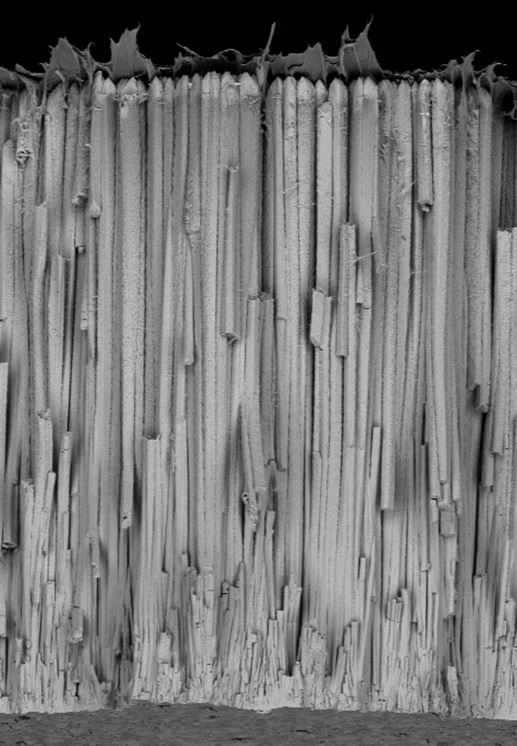

Traditionally, Scintacor has produced FOS caesium iodide (CsI) X-ray scintillators. These are made up of a layer of CsI deposited on a fibre-optic faceplate (FOP) and then coated over with a protective film. The faceplates are composed of compressed bundles of glass optical fibres which transfer the photons created in the CsI layer when bombarded with X-rays, to the CMOS/CCD sensor the FOP is bonded to. Due to the light guiding properties of both the CsI and the optical fibres in the FOP, the bright image created in the CsI is transferred to the sensor with minimal loss of resolution.

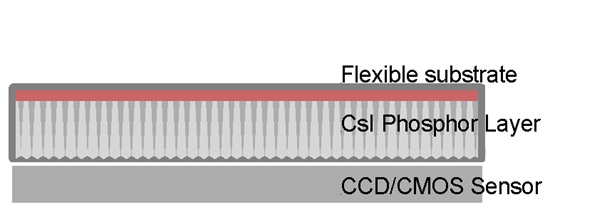

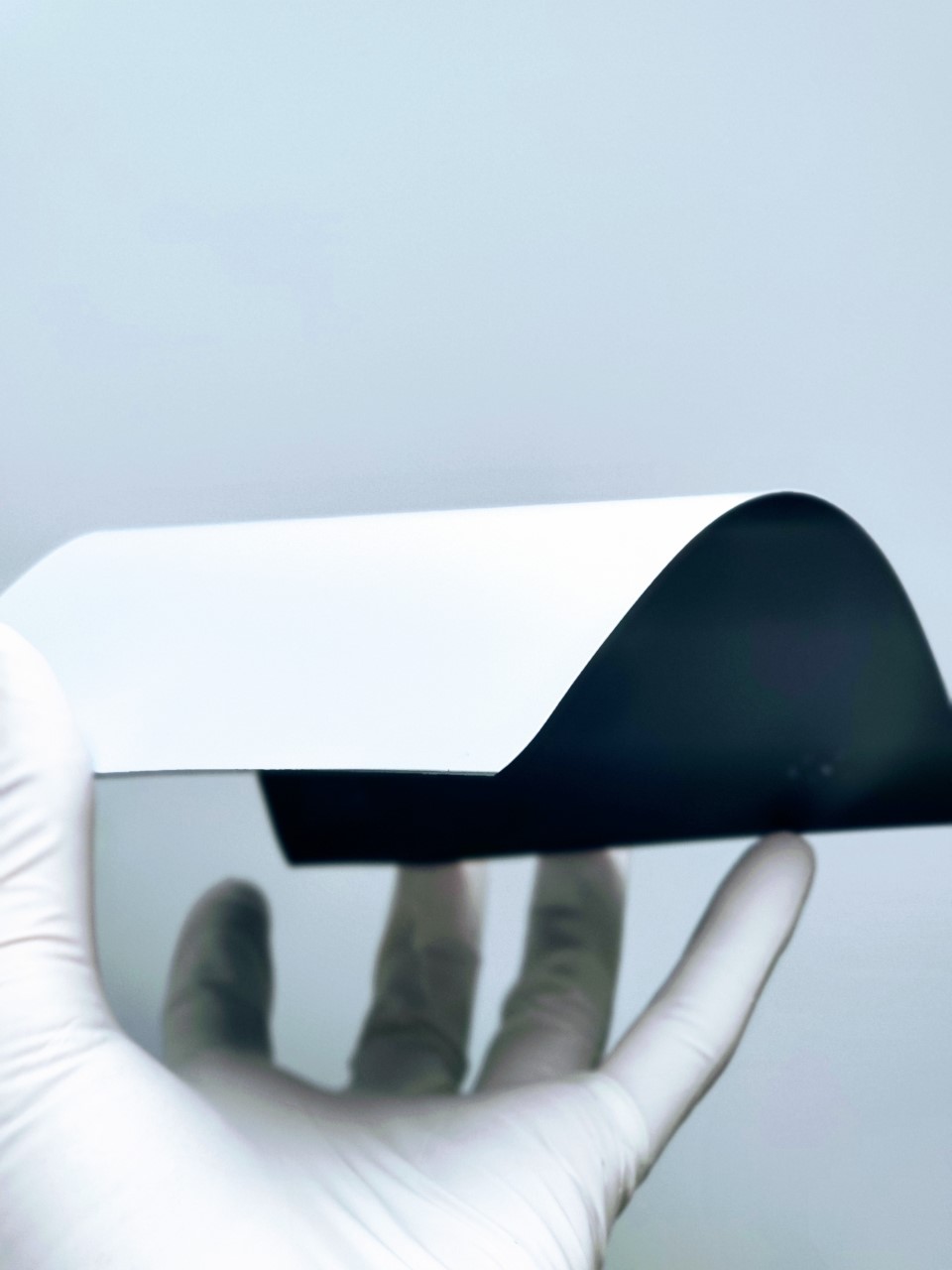

Scintacor has developed a product where the CsI is deposited on a thin flexible substrate which is easily cut to shape before deposition. The CsI and substrate is encapsulated in a protective film and remains flexible. This allows the scintillator to be easily laminated to a sensor or FOP or even to be used on a curved sensor or FOP.

.

In this new product the light comes out of the tops of the columns and into the sensor or FOP via a protective layer. The substrate protects the top of the device- being on the side of the CsI that the X-rays enter, and the device is pressed in position against the sensor or FOP. In the traditional FOS device, it is the other way round with the light exiting the bottom of the CsI columns and going to the sensor via the FOP on which the CsI is grown. Both types of scintillator work equally well and have similar X-ray performance. The flexible substrate can be reflective or black to change the brightness/resolution balance.

Scintacor’s Flexible CsI Scintillators are available with areas up to 310 X 310 mm2 and the CsI layer is 100 µm to 600 µm thick. They are available in high resolution and high light output versions. Applications include dental CT, surgical C-arm, fluoroscopy, mammography, scientific X-ray, pathology and electronics inspection.

Author Martin Lewis – Principal Engineer