Download the full article SC-AN-DentalImaging-001-Rev01-Jun22

Andrew Headon – Graduate in Physics from the University of Bath, has been a Development Engineer at Scintacor for five years and is part of the team developing new products based on Caesium Iodide (CsI) for OEM Dental applications. “We develop new products, define how to manufacture these products at an industrial scale, and then roll those processes over to the production team”.

Background

Caesium Iodide (CsI) is a scintillator commonly used in industry for dental X-rays for both intraoral and extraoral applications. The purpose of CsI is to convert X-ray radiation into visible light so that cameras are able detect light and be able to take an image.

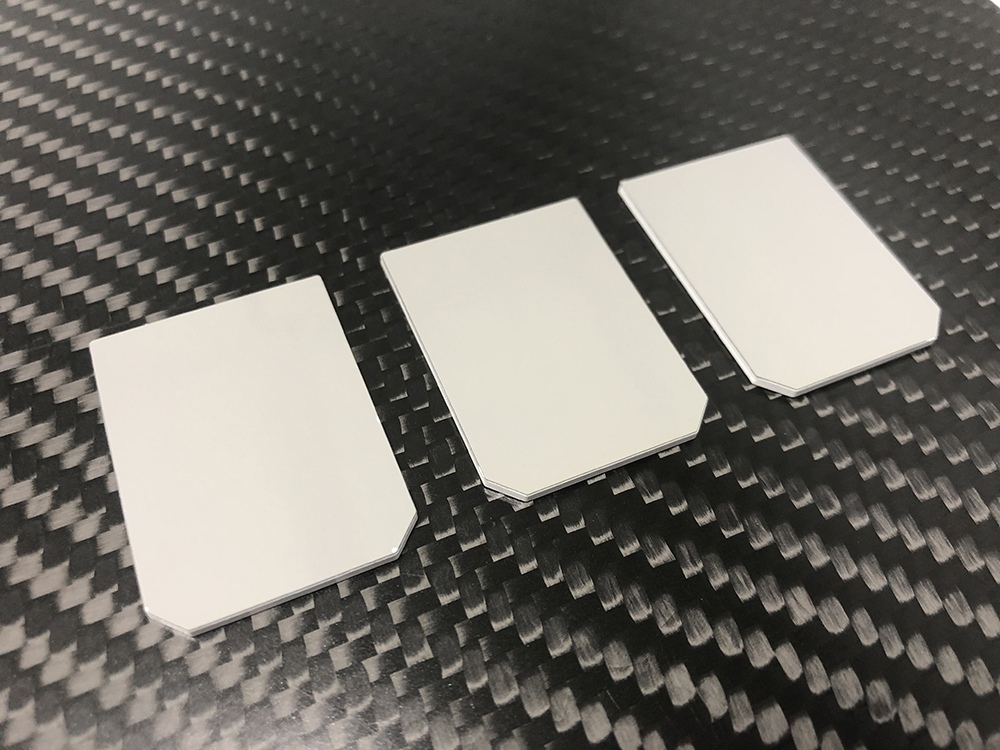

We supply our dental camera manufacturer customers with intraoral scintillator sensors which are small sensors that go inside your mouth so that dentists can image your teeth and specific areas your mouth.

We will typically produce anywhere from 200 to 1-2 thousand parts per month for our OEM dental customers.

Scintacor expertise – due to space limitations intraoral sensors need to fit comfortably inside the mouth. Scintacor maximise the imaging area on the sensor by depositing the CsI layer as close to the edge of the sensor as possible, which allows the housing to be designed to keep the overall finished part as small as possible. We have perfected this process and have even smaller sensors for children.

For other dental OEMs we make extraoral sensors which go around the outside of your mouth, scanning for example the whole jaw, sometimes the whole skull. These sensors can be good for getting an idea of what the whole jaw looks like and decide if your teeth or jaw need any structural work.

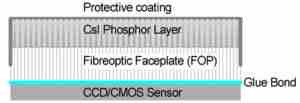

Typically, the CsI will be deposited onto a fibre optic plate (FOP), and that will then be bonded to the customer’s camera sensor. We deposit the CsI as closely as possible to the edge of the FOP to enable high image quality in the largest size possible. With extraoral parts you are less restricted on space and the detector could be slightly larger. Customers might have more room for electronics around the parts, but we can often use the technology that we have developed for intraoral parts, so that we still have CsI as close to the edges of the FOP, reducing the size of components and avoiding the use of excess materials to reduce waste and cost.

The Scintacor Solution

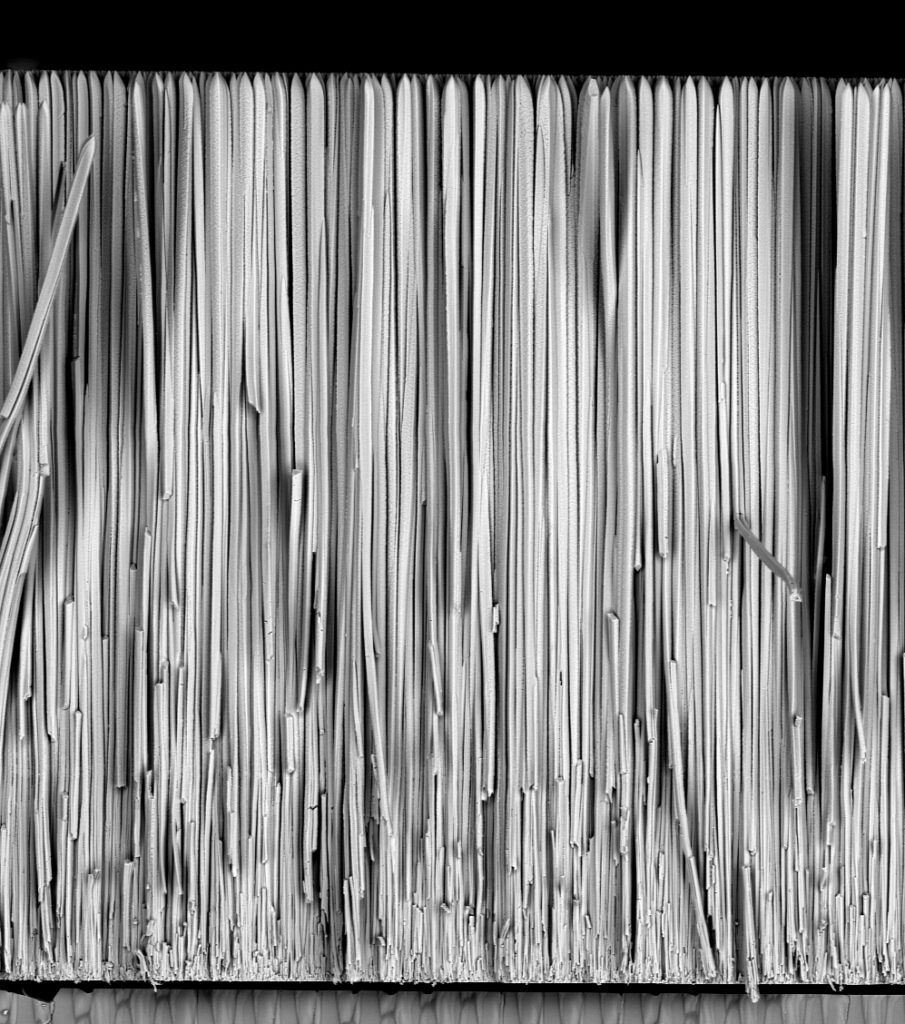

Scintacor is the world’s leading specialist of thin film

deposition in micro columnar CsI layers with micron sized CsI crystals. The CsI crystals allows high resolution images from the sensors without losing anything in terms of light output. CsI tends to be an excellent choice for dental and imaging processes due to the high resolution and lower afterglow and decay times. The lower afterglow allows the acquisition of videos with high frame rates. Scintacor has produced micro columnar CsI layers for years. We can deposit onto different substrates such as various shapes of FOPs, onto plastics like PET or polyimide, metal substrates, or even 3D structures like lenses. At Scintacor we are very keen on collaborating with customers to find solutions for them that may not exist or may not be as easy to achieve with other manufacturers

Alternative substrates

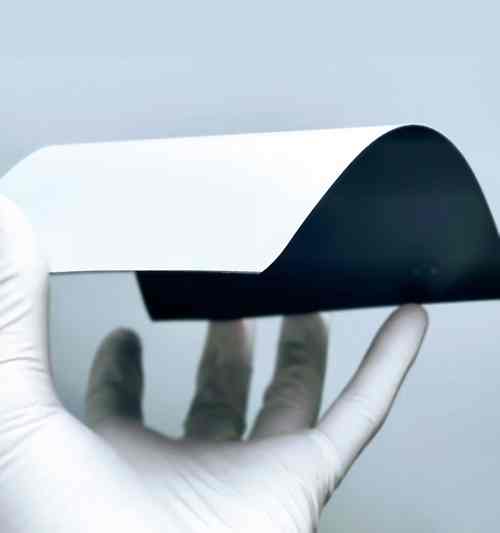

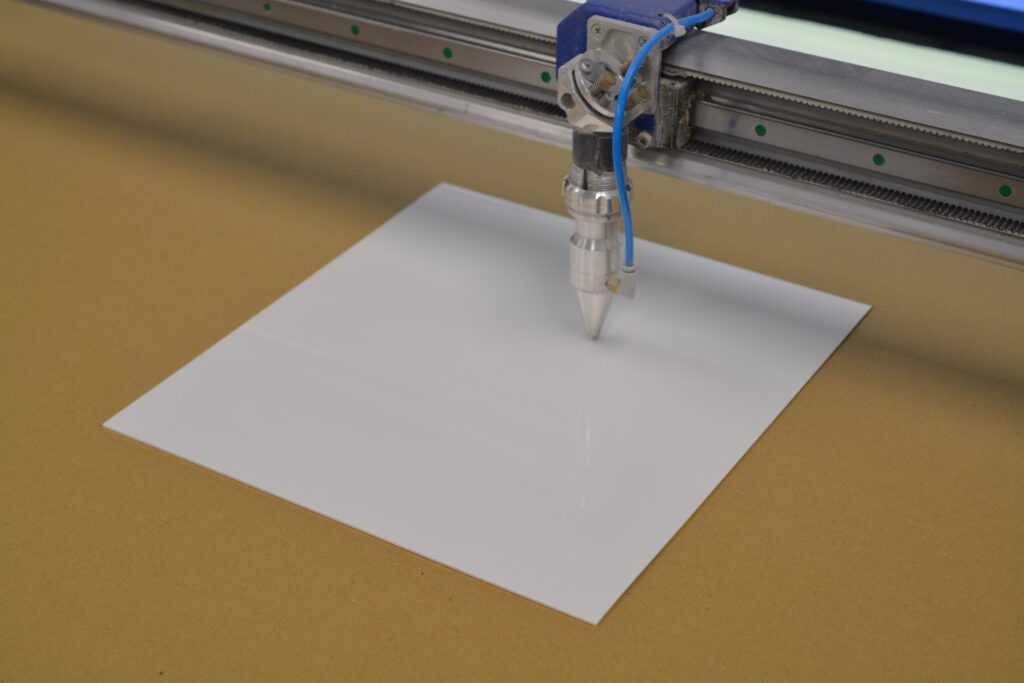

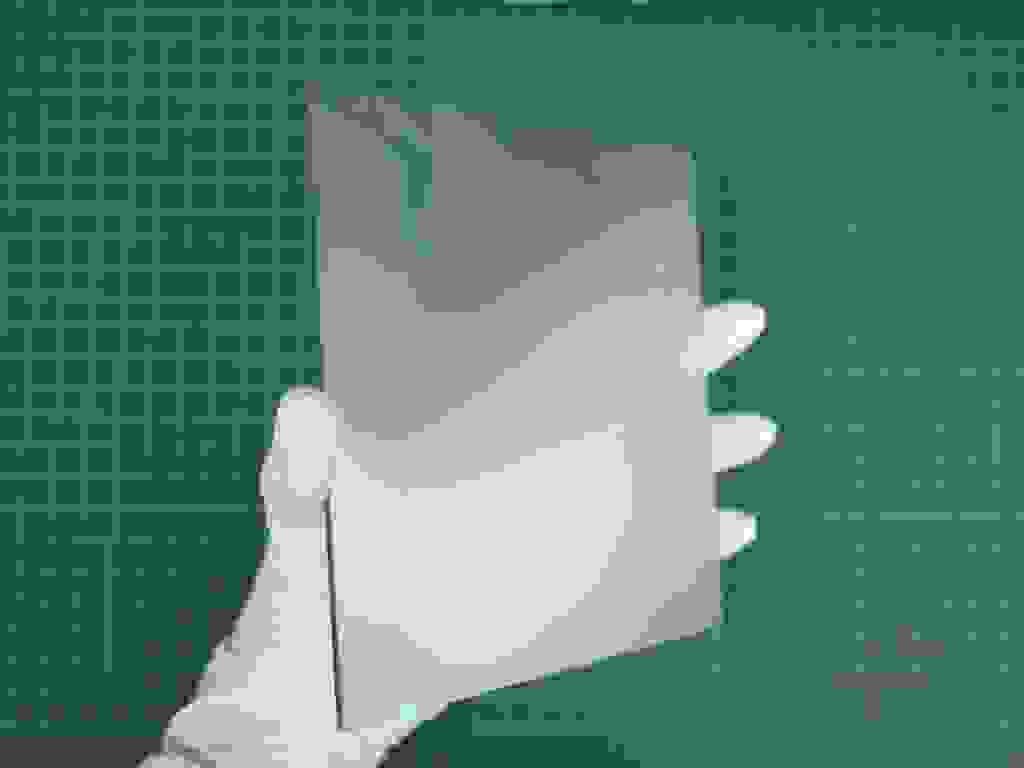

As well as rigid FOPs we can deposit CsI onto flexible substrates such as plastics like PET or polyimide. These can be adapted to unusually shaped devices or they might just be chosen for ease of handling. In certain scientific applications cameras require interchangeable scintillators that can be swapped to provide different scintillator thicknesses for different performances. As they are robust, these flexible substrates can be easier to manipulate without damaging the edges. They can have very minimal borders around the edges or can have large borders if the customer wants to be able to clamp onto something on the edges. Thanks to the nature of the substrate, they can becut into any shape, from a few millimetres in size up to about 31 centimetres. To ensure dimensional accuracy all parts are cnc cut to size.

Energy Ranges and Safety

The majority of X-ray sources that we work with are in the 70 to 100 keV range although CsI can work with both lower energies and up to energies in the hundreds of keV.

X-rays are absorbed by the CsI in our products which then

converts this energy into visible light. We collaborate with

customers to tailor the thickness of the CsI to match the X-ray source that they are using to maximise X-ray absorption. This protects against the chance of damaging patient cells and damaging the camera sensor whilst minimising image noise. Correct choice of FOP will further absorb X-rays, which adds to patient safety as well as protecting the camera sensor.

CsI is a very versatile Scintillator material

Other than dental applications, CsI can be deposited onto

larger areas (up to 31cm square) for medical mammography, chest X-rays, and veterinary applications. It can also be used in baggage scanners or other security applications where a detailed image is required of what is inside an object or vehicle.

Scintacor is dedicated to product performance & customer satisfaction

With 30 years of experience in the dental industry we have extensive

resources, past experience and knowledge to draw upon. We

collaborate closely with customers to tailor the product to their

specific needs, whether that be for a small one-off product for

the university researcher or for large scale batches of thousands

for OEM applications. Scintacor is dedicated to product

performance and customer satisfaction.