Direct Deposition of Caesium Iodide

Direct Deposition of high performance Caesium Iodide (CsI) on Silicon Sensors

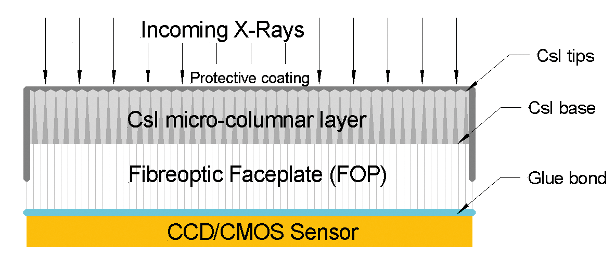

Scintacor will directly deposit CsI onto your CMOS sensor as an alternative to the more usual

FOP-based (fibre-optic faceplate) scintillator.

Simplified Assembly

With FOP-based scintillators, light signal from x-rays travels through the ‘tips’ side of the CsI layer and then through the FOP that is attached to the sensor chip.

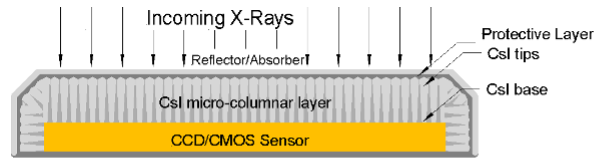

With Direct Deposition devices, there is no FOP. The CsI is deposited directly onto the sensor and light signal from x-rays travels directly to the sensor. More signal reaches the sensor and no FOP attachment stage is required.

CsI deposition

Scintacor has extensive experience in CsI deposition and can tailor the manufacturing process to optimise the outcome. We can provide expert advice on the many aspects of direct deposition on sensors, including:

- Impact of sensor topography

- Electrostatic protection during coating

- Protection of electrical contacts

- Impact of deposition on sensor wire bonds

X-ray performance

With the CsI layer in intimate contact with the sensor, the x-ray performance, ie. brightness and resolution, is noticeably better than that obtained by attaching an FOS. The exact performance depends on sensor design as well as the CsI thickness and reflector/absorber applied.

With Direct Deposition, it is the CsI layer rather than the FOP which is the primary x-ray blocking layer; as a result, direct deposition scintillators are more prone to sensor direct hits than traditional FOP-based devices and these can have a significant impact on signal to noise ratio (SNR).

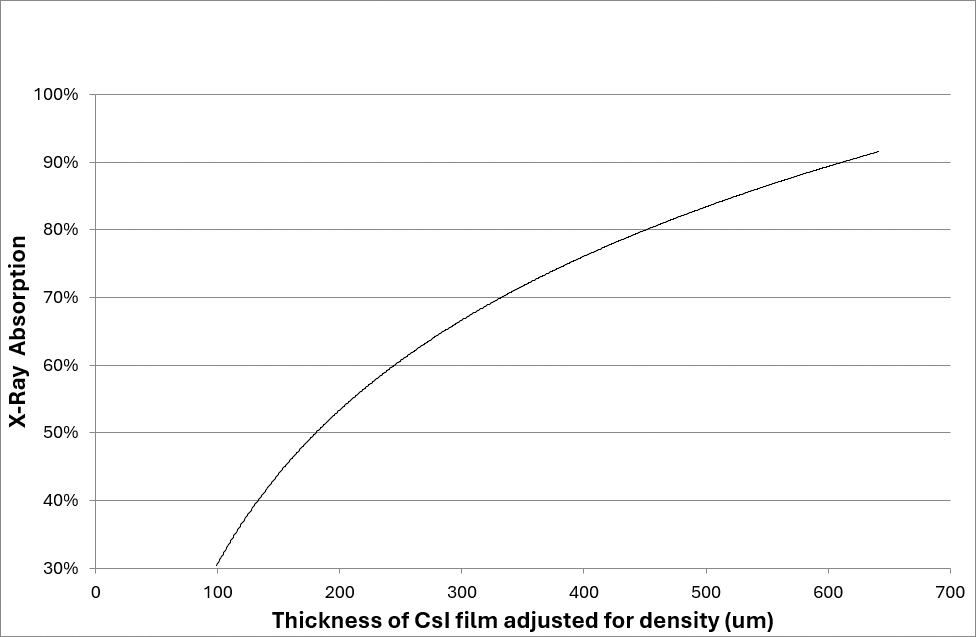

The plot below shows the x-ray absorption for different thicknesses of the CsI layer.

Typical applications

- Intra-oral dental

- Dental CT

- Fluoroscopy

- Mammography

- Scientific x-ray

- Pathology

- Electronics inspection (NDT)

- Security

Why Scintacor?

Scintacor has a wealth of experience manufacturing and developing CsI based products using a variety of substrate materials including glass, aluminium and polymers. We continuously improve and extend our capabilities to meet the needs of your applications, tuning the CsI structure for maximum performance and to offer a large range of customised build parameters. Please contact us to discuss your specific requirements in more detail.

Benefits & Features

- High resolution micro-columnar CsI scintillator layer.

- High sensitivity solid state scintillator to reduce

patient x-ray dose. - Simplified structure where the CsI scintillating layer

is deposited straight onto the sensor surface eliminating

the high-cost coupling FOP, and improving image

resolution and brightness. - Choice of finishes to the face of the CsI layer:

o Black for high resolution, low brightness.

o White for higher brightness and correspondingly lower resolution applications. - Choice of CsI thickness to balance brightness, SNR,

and resolution; from thin layers used in intra-oral dental

devices, to much thicker layers for high energy and

high SNR x-ray applications. - Full encapsulation to seal CsI against the ingress

of moisture.

Downloads

Technologies

Contact Us

+44 (0)1223 223 060

info@scintacor.com

Contact Form