The excellent sensitivity and robustness of our phosphor-based intensifying screens allow for reliable, high-resolution X-ray imaging for mail, parcel, baggage, and cargo inspection and for use in industrial NDT, health and safety, and quality control.

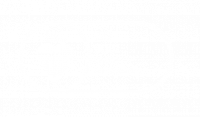

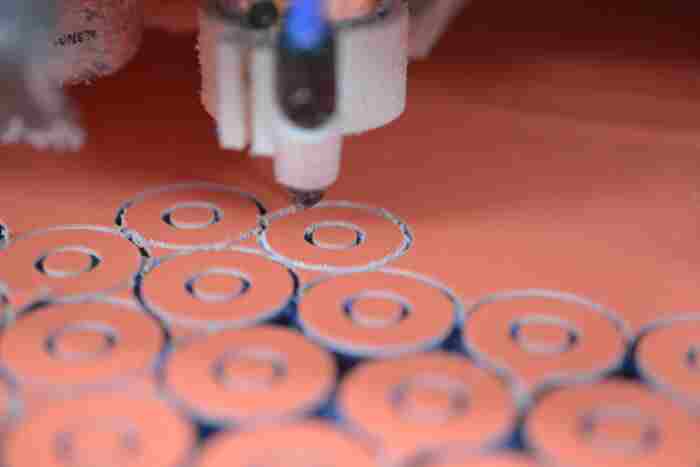

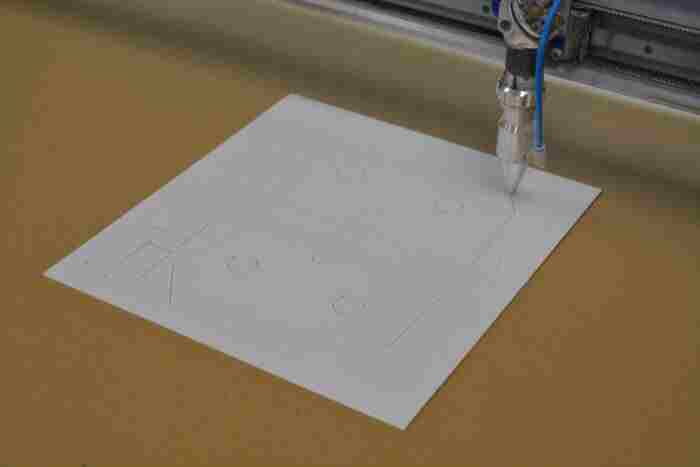

Scintacor’s in-house laser cutting and CNC milling systems means that we can fully customise the size and shape of our screens to match the specific requirements of our customer’s application. The screens can be manufactured up to a maximum dimension of 100cm x 170cm and accurately cut to the customer’s specific, and sometimes complex, shapes. This enables us to supply pre-cut kits of screens ready to use on the customer’s production line.

We can also supply highly toleranced strips for linear detector arrays. These strips are particularly useful in high throughput applications.

Our screens can be manufactured to include a thin cover layer to protect the integrity of the phosphor during transport and handling.

We also have the capability to supply the screens as self-supporting sheets or mounted to a variety of materials and a wide range of mountings and support materials are available, such as aluminium, bakelite, and perspex.

With size and shape, emission spectra, decay time and X-ray absorption characteristics customisable to your requirements, we can design and manufacture each screen to suit your exact application and operational demands.

Find out more about Scintacor X-ray scintillation screens or contact our sales team to discuss your requirements.